ON-SITE DAMAGE ASSESSMENT

Prevent hazards & safeguard

If damage occurs, the top priority is to continue to prevent hazards or to safeguard the environment, and contain further risks to humans and the environment. The second stage must be to plan damage analysis and to define the type and scope of the investigation stages. Here, it is highly important to secure evidence at the area of damage. If proof or information is not adequately collected or unintentionally destroyed, the probability of being able to conduct a fact-based analysis is reduced and the degree of presumptive analysis increases.

However, only a fact-based analysis gives you the possibility of reliably eliminating errors and weak points in processes and structures in the future.

In this context, we can offer you the following services:

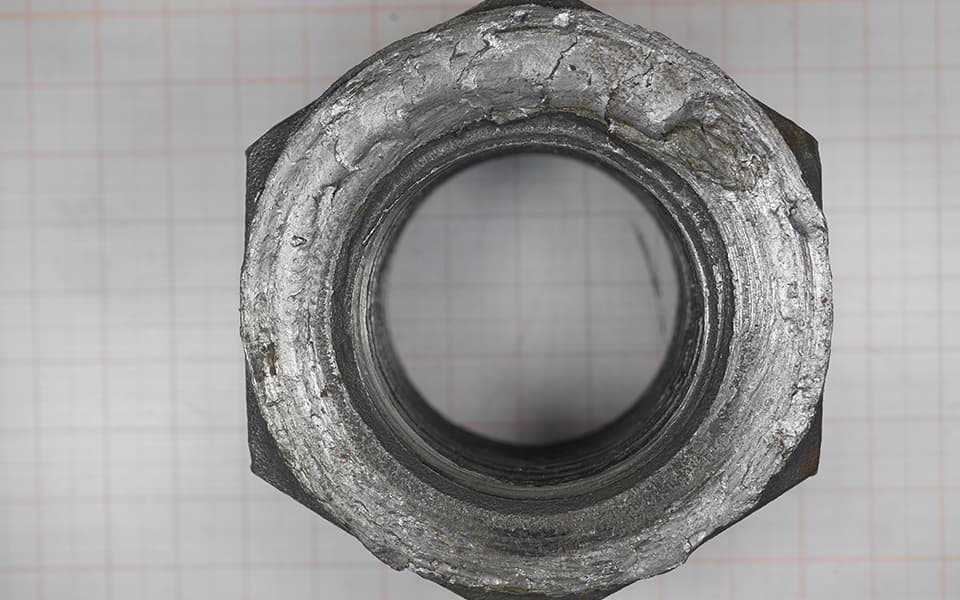

- Analysis of the flange connection on site after the leakage has occurred.

- Root cause analysis: How was the flanged joint fitted? Are there signs of a lack of care during assembly? Were the correct components used?

- Support in disassembling leaky flanged joints at your premises.

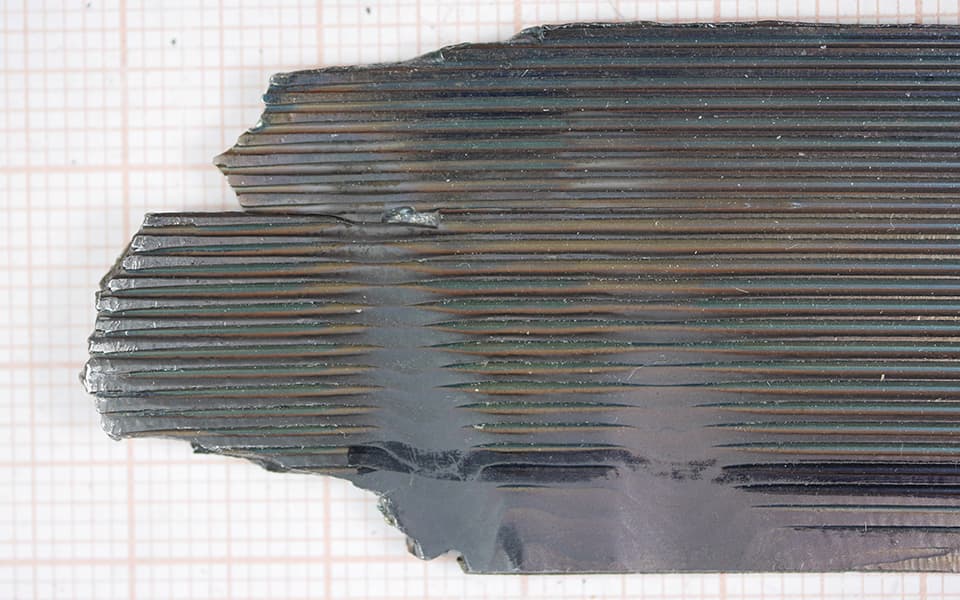

- Exact documentation of findings when the flanged joint is opened.

- Securing, labelling and packing the used components and transporting them to our labs for investigation.

- Survey and analysis of the secured components in our chemical and physical labs for the effective identification of any systematic errors.