METAL GASKETS

» METAL PROFILE GASKETS

» ROUND WIRE GASKETS

» RING-JOINTS RTJ

» LENS GASKETS

» DIAMOND GASKETS / H-GASKETS

» WELD RING GASKETS

» DOUBLE-CONE GASKETS

» DELTA GASKETS

METAL PROFILE GASKETS

Solid profile gaskets made of metal where soft materials are overstrained

Solid metal flat gaskets are used in areas where, due to the medium, temperature, pressure and/or permitted leakage rate, soft-material or metal/soft-material gaskets are not particularly suitable. They have proven reliable at low temperatures of -200 °C as well as at high temperatures of over 600 °C. They are used at pressures ranging from relatively low to extremely high.

The thickness of the seal and the sealing material are generally dependent on the flange surface and the operating conditions. The better the flange surface in terms of surface quality and evenness, the thinner the gasket that can be used, e.g. 0.5 – 1 mm as a gasket in spinning nozzle fittings or 2 – 3 mm for aluminium gaskets in heat exchangers.

It should be noted that soft metals (such as aluminium or silver) need only relatively low surface pressures to become deformed, harder materials on the other hand, particularly steel, require high sealing pressure.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

ROUND WIRE GASKETS

Your professional for round wire gaskets

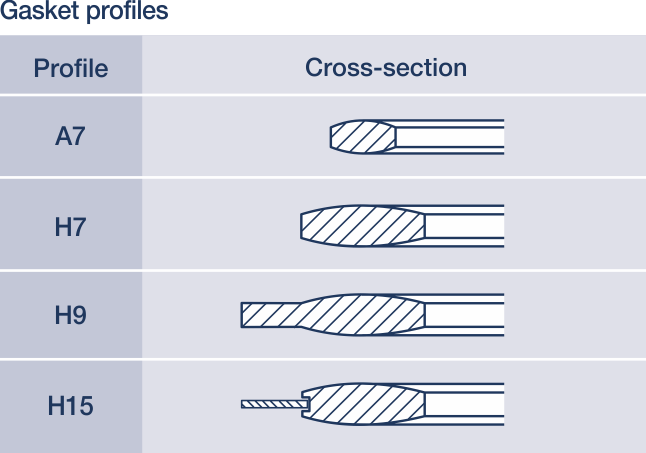

Round wire gaskets are used in gas and vacuum engineering. Standard materials used include soft-annealed aluminium, copper, silver and nickel.

Lathed rings and rings bended and welded from calibrated wire can be supplied. Round wire gaskets are usually inserted in grooves. Some possible options are shown here.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

RING-JOINTS RTJ

We produce high-quality ring-joint gaskets according to international quality standards

Ring joint gaskets are made from metallic materials. The requirements in terms of dimensional accuracy and surface quality are therefore high. This relates to both the gasket and the sealing section of the flange.

The necessary surface quality depends substantially on the Brinell hardness of the gasket material. The relationship

Rz [m] ≤ 300/HB provides a useful indication.

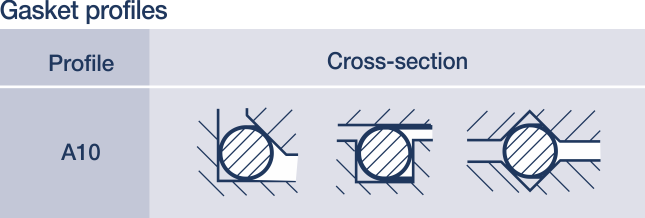

A distinction is made between two kinds of ring joint gaskets and two different calculation methods are therefore used:

1. RTJ gaskets with osculating radius (Figure 1)

2. RTJ gaskets with flat sealing surfaces (Figure 2)

Ring joint gaskets according to API and ASME standards are mainly used in the petrochemical industry and refineries as a reliable seal for production lines. We are authorized to mark our products with the API quality stamp. We thus guarantee that our products are designed according to the latest API standards.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

LENS GASKETS

The proven high pressure seals

Lens gaskets are reusable, as the sealing effect is generally achieved by elastic deformation of the surfaces.

Lens gaskets are impervious to overpressure. With increasing loads, the contact surface between the spherical lens surface and the spherical flange groove increases, so that the surface pressure only increases to a lesser extent.

We can also specially produce bellows lenses, lens blind spectacle gaskets and half-lenses.

Lens blind spectacle gaskets are made of a sealing lens and a lens blind, which are connected by a ligament. It is also usual to use lens blinds on their own. In this case, it is useful to weld on a small plate to render the lens blind distinguishable.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

DIAMOND GASKETS / H-GASKETS

Diamond gaskets have proven excellent in high temperature engineering, high vacuum engineering, chemical and petrochemical industries as well as in nuclear technology. Diamond gaskets are metallic gaskets. Like all metal gaskets, they require high sealing surface pressures.

As it is the ”tip“ of the diamond that bears pressure first of all, the necessary forces are much lower compared to other metal gaskets.

So that the diamond gasket does not damage the flanges, the gasket should have a lower hardness than the flange material.

In stainless steel flanges the diamond gasket is made of the same material. Gasket and flange have roughly the same hardness.

Diamond gaskets are also used with an inner or outer centring ring.

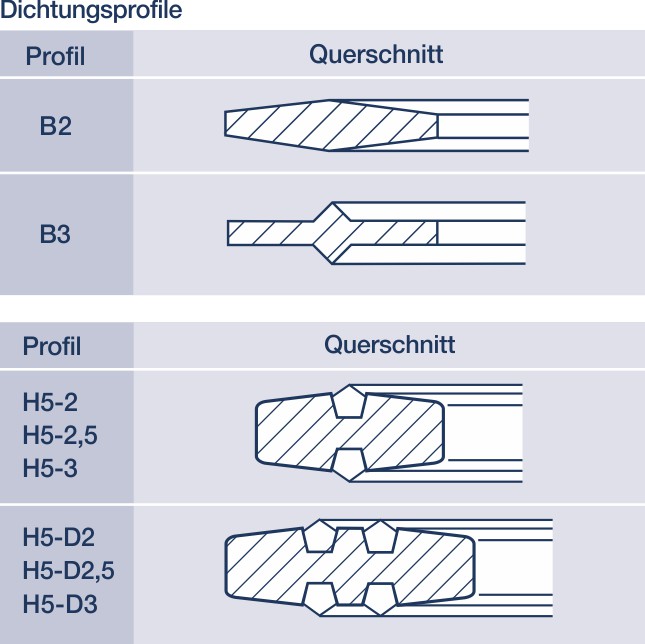

The H-Gasket

A further development of the spike edge gasket is the H-gasket. The H-gasket is an all-metal gasket consisting of a chamber ring and two or four sealing rings.

Special features of the seal Profile H 5 are:

- low sealing forces

- kein Setzen während des Betriebes

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

WELD RING GASKETS

Welded sealing connection with know-how

We recommend weld ring gaskets for use in any place where a welded seal is necessary, due either to the danger of the medium or the danger presented by a loss of functionality, but where the connection also needs to be detachable to a certain degree.

These gaskets are therefore described as being semi-detachable, as the welded sealing joint needs to be undone as well as the flange bolts.

Weld ring gaskets are generally made of the same or a related material as the pipe or flange and are only used in pairs.

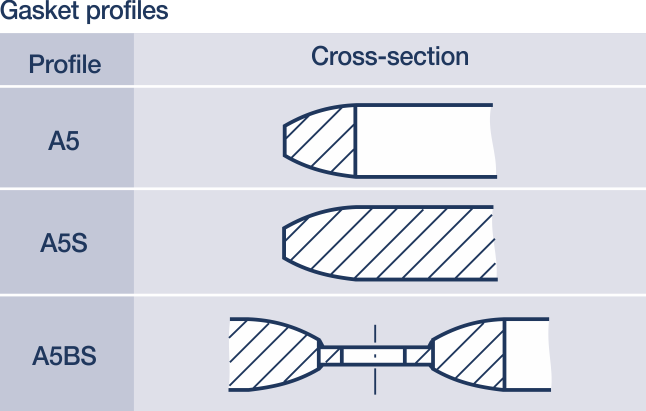

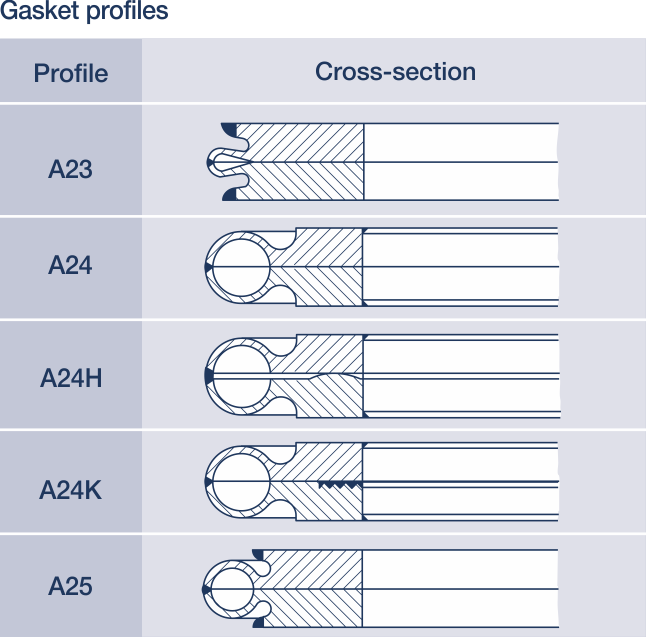

The choice between the various profiles depends on the operating conditions of the weld ring gasket. The table shows the typical features of Profiles A21 to A25. The ”attachment seam“ is the connection of a welded half with the flange. The ”attachment seam“ can be located internally or externally. The ”seal seam“ is always the welding of both weld rings with one another.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

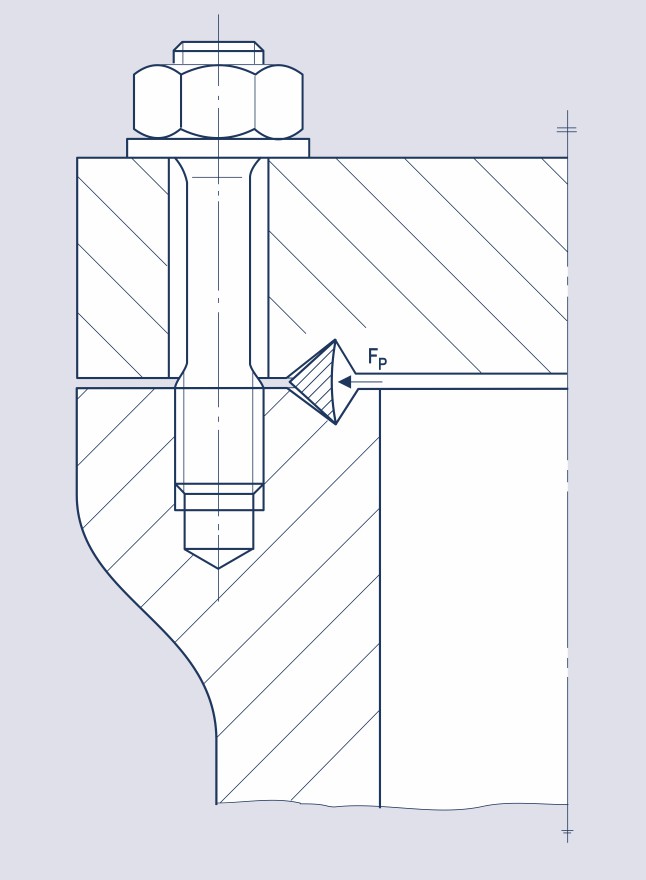

DOUBLE-CONE GASKETS

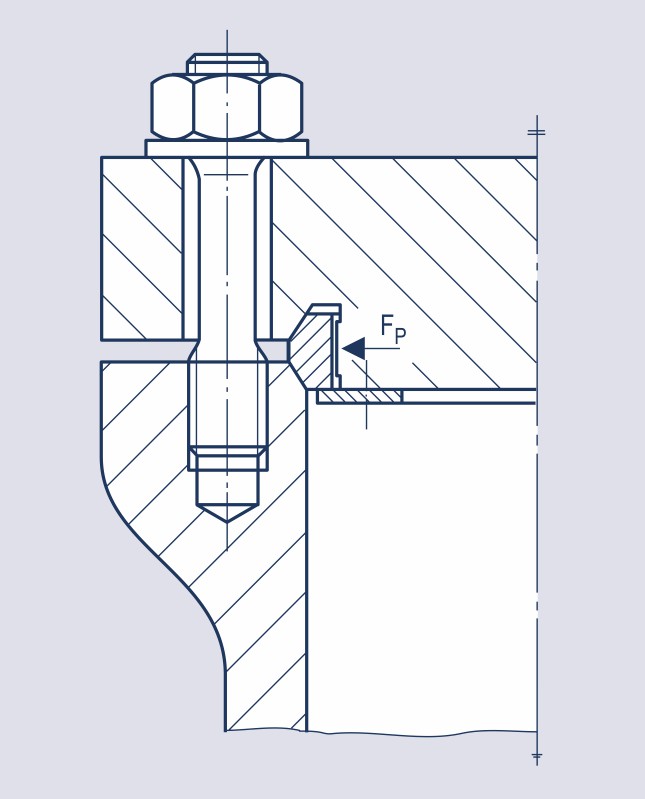

Double-cone gaskets are radially compressed like a circular spring by the bolt pre-tensioning force. A pre-tensioning of approximately 1/3 to 1/5 of the test pressure is generally sufficient to achieve the necessary initial seal. So that the gasket does not become overloaded, only a limited amount of clearance should be left between the cover and the gasket. After pre-tensioning the gasket will initially have contact inside to the cover. With the application of pressure it will then spring back by the compressed amount and if there is sufficient internal pressure will expand elastically, so that it offers reliable sealing in all operating conditions due to its optimal design shape.

We would be happy to carry out a cost-efficient check for tracking and to determine the measurements of the double-cone gasket as part of our gasket estimate service. The illustration above show the design principle.

The measurements of double-cone gaskets are not standardised. We can currently supply sealing rings up to Ø 3200 mm. The sealing surfaces are conical surfaces with a sloping angle a. A sloping angle of α = 30° is usual, but is not suitable in every case.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

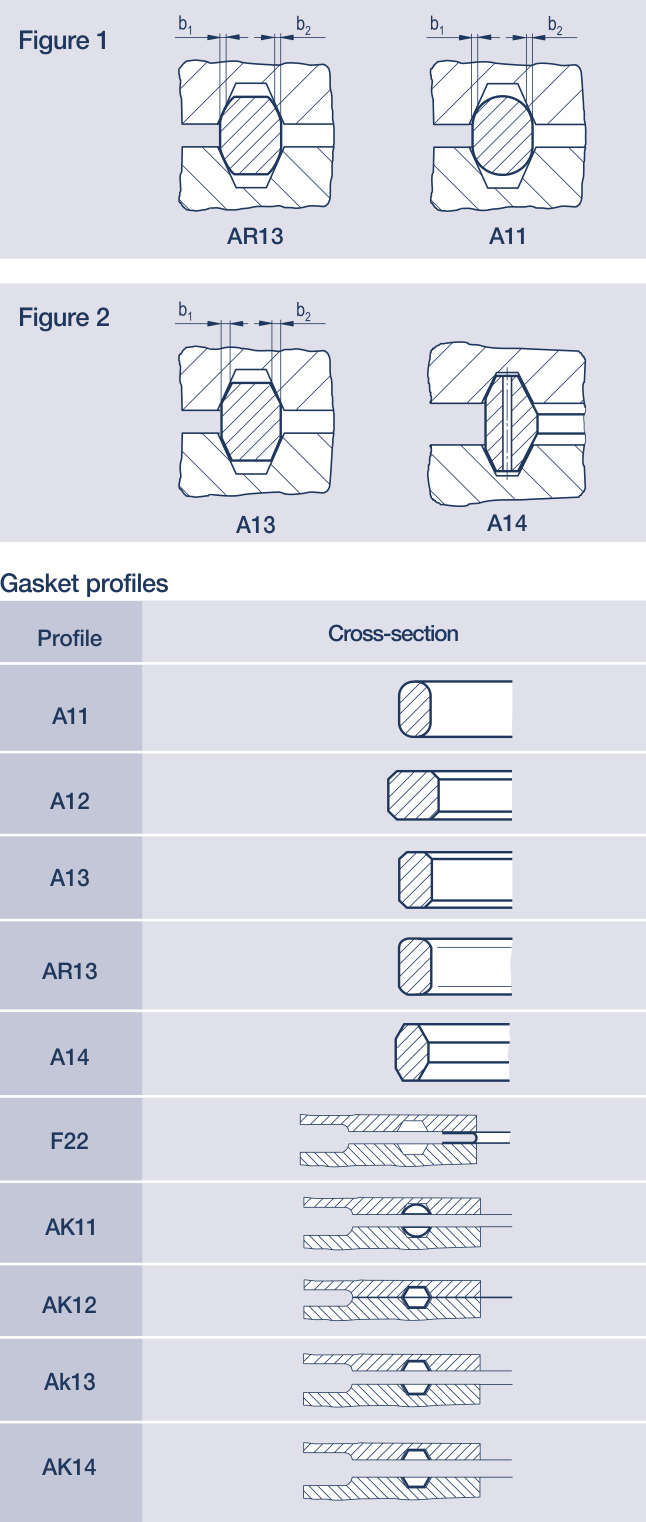

DELTA GASKETS

Because of their geometric shape, delta gaskets require a higher level of precision from the seal grooves. As a direct result of the manufacturing process and its resulting precision, delta gaskets are only used for high-pressure autoclaves and high-pressure connections up to a maximum of 2000 mm, whereby the majority are less than 1000 mm. The following illustration shows the application as a cover gasket.

Due to its splined profile, an excellent initial seal is created by the partial plastic deformation of the opposing peaks of the gasket when bolt pre-tensioning force is applied. The radially self-sealing effect arises due to the high internal pressure resulting from the elastic extension of the gasket.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.