» FLAT GASKETS MADE FROM GRAPHITE, FIBRE, PTFE, ELASTOMER

» KLINGER®-TOP-CHEM

» SPECIAL GASKET WAVELINE WLP®

FLAT GASKETS

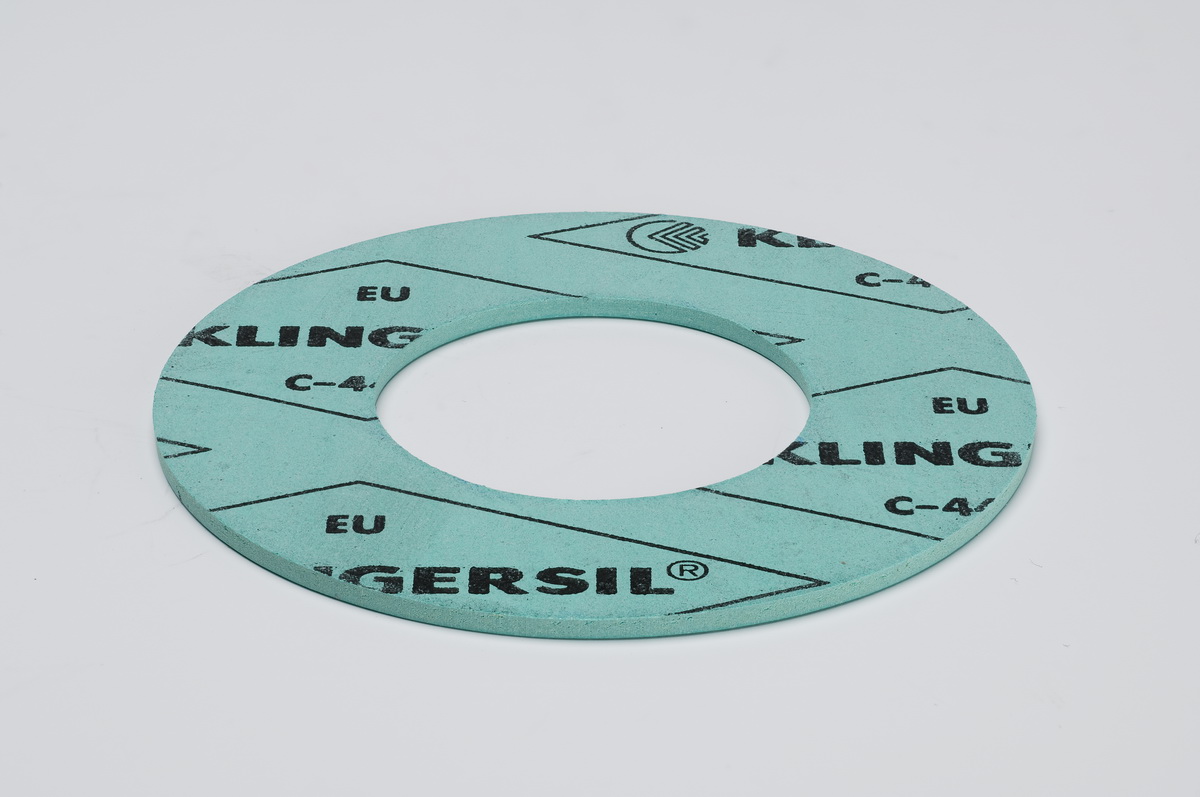

Flat gaskets are universal sealing elements with a large range of application in all branches of industry. They can be used within a temperature range of – 200 °C up to a maximum of + 550 °C. A suitable material should be selected depending on the medium, medium concentration, temperature and type of flange being used.

We produce flat gaskets in all commonly-used soft materials.

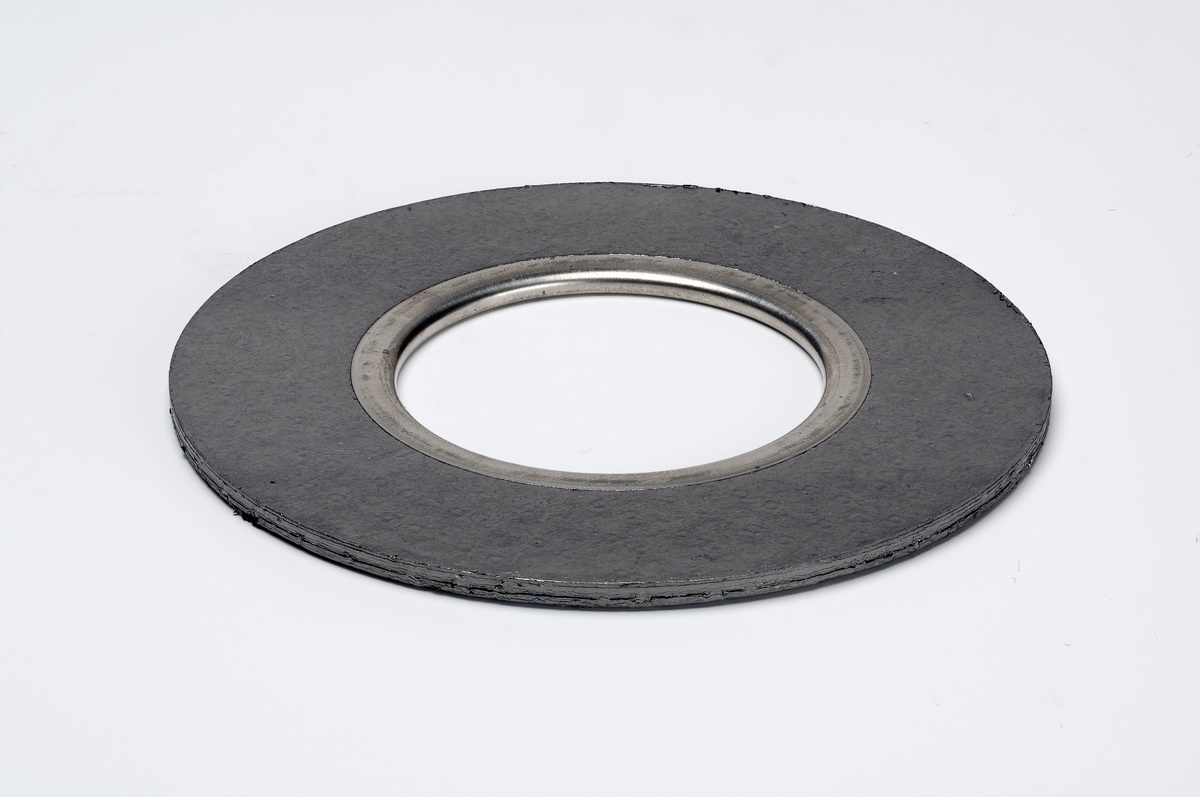

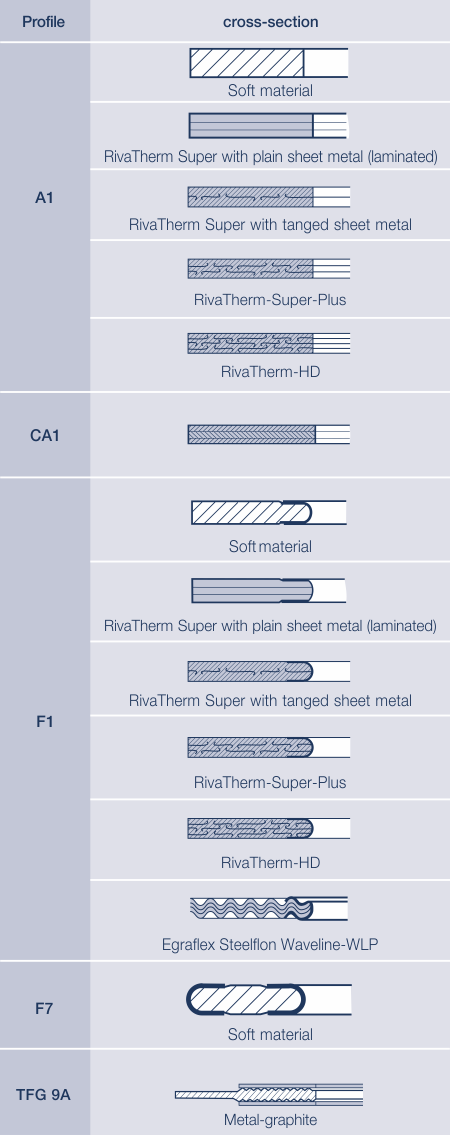

Flat gaskets made from soft material are available in ring shape, as frames, as oval gaskets and practically any other special kind of shape. To close the porous interfaces in fibre sheet gaskets (FA) or in expanded flexible graphite or RivaTherm Super, gaskets are rimmed on the inside with a thin metal band

Gaskets with outer rim made of a thin metal band are used where the media wear comes from the outside. This is the case, for example, with self-sealing manholes, head access hole locks or even in construction apparatus, if internal fixtures need to be sealed.

KLINGER Kempchen also manufactures seals for special applications and according to individual requirements and finds special solutions for your needs. We have highly trained and competent professionals for gasket calculation, who select and match the materials for you.

Have a look at our homepage KLINGER ENGINEERING, you will be surprised about the engineering services we offer.

FLAT GASKETS MADE FROM GRAPHITE, FIBRE, PTFE, ELASTOMER

The usual thickness of gaskets is 1; 1.5; 2 and 3 mm. PTFE gaskets should be used in the thinnest size possible due to cold flow.

Therefore, the surface quality and evenness of the flanges is decisive for the gasket thickness to be selected. The better the flange surfaces, the thinner the gasket thickness may be. Soft gaskets require only low pre-deformation surface pressures sV, but can also be overloaded more easily than metal gaskets or metal-soft gaskets, especially with narrow gasket widths.

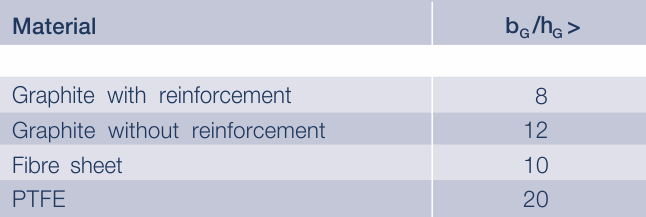

In order to avoid collapse, the sealing surface pressure must be between σV and σϑ and the following width/height relationships must be complied with:

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

KLINGER®-TOP-CHEM

Sealing technology on a new level

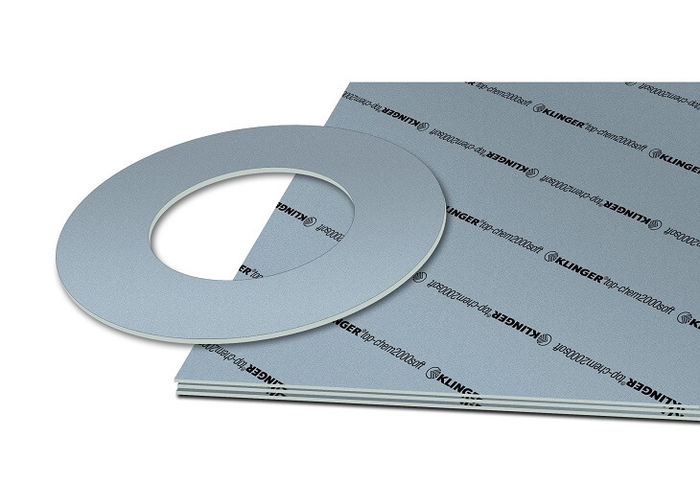

Soft material flat gaskets from KLINGER®top-chem

The top qualities of the range allow you to benefit from the advantages of PTFE seals without having to put up with the usual disadvantages. With KLINGER®top-chem you can clearly push the limits of what is possible. You save working time and gain plant safety.

With our seamless coverage of all applications and hugely detailed description of the performance features of each product, you can avoid any gaps in security.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

SPECIAL GASKET WAVELINE WLP®

Solutions for special tasks

The use of toxic, environmentally harmful or simply expensive gaseous media places extremely high demands on the sealing technology with the goal of very low emissions.

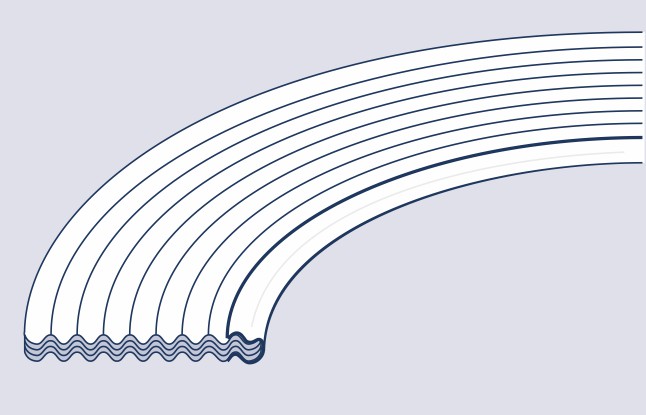

Structure

The Waveline WLP Egraflex Steelflon gasket Profile 1 with inner eyelet has a corrugated cross-section which is under high pressure due to the corrugated stress. This sealing material is a sandwich design of pure graphite and metal sheets. The internal design consists of several 0.5 mm thick layers of high-quality graphite sheets and 0.05 mm of plain stainless steel sheet foils.

Advantages

The inner eyelet is pre-compressed using the Waveline® process and reduces the diffusion of the medium through the seal. This produces very low leakage rates, even under normal operating conditions.

The Waveline WLP® Profile F1 with inner eyelet fulfils the requirements of TA Luft in accordance with the VDI Guidelines 2440.

The metal reinforcements and the stable 0.15 mm thick inner eyelet, combined with the corrugated pre-compression, ensure that the gasket is inherently stable and easy to handle.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.