EXPANSION JOINTS

FABRIC EXPANSION JOINTS

RUBBER EXPANSION JOINTS

METAL EXPANSION JOINTS

LINING JOINT SEALING

REAFLEX AND REATEX

FABRIC EXPANSION JOINTS

Several decades ago, when Kempchen first began producing soft-material expansion joints, metal expansion joints were still predominantly being used in the field of power plants and chemicals.

Today, KLINGER Kempchen soft-material expansion joints have found a solid range of applications. Without these versatile assembly parts, modern industrial plants would not be possible. Without the use of soft-material expansion joints, the costs of such plants would be considerably greater.

The main advantage of soft-material is the multidimensional absorption of movement despite having very low reaction force. Their superior movement absorption allows for cost-effective piping, while their low reaction force perwiths cost-effective fix point construction.

KLINGER Kempchen has developed a patented method for sintering PTFE sheets onto all types of fabrics. This has brought significant improvements to the properties.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

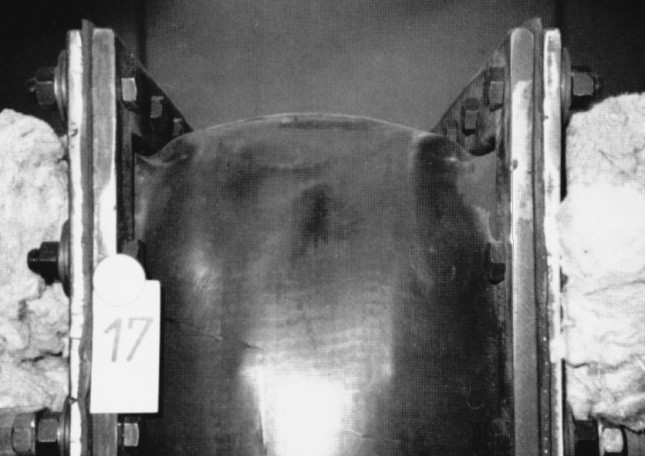

RUBBER EXPANSION JOINTS

Design 1 + 2

Design 1 with rotating flanges

Highly elastic pipe connectors

For all sectors of industry, apparatus and pipeline construction, power plants, shipbuilding, fuel pumps, heating, climate control and ventilation plants, etc.

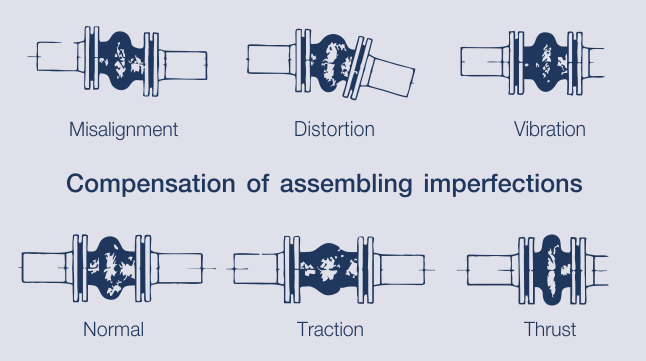

Use

Absorption of axial and radial expansion, noise, vibrations and oscillations. For subsidence of buildings and containers, assembling imperfections, for electrical insulation, for nearly total noise absorption in pipelines, domestic supply mains, heating systems, pump and motor connections.

Design 2

KLINGER Kempchen rubber fabric expansion joints with an extremely robust design for use in pipeline construction, shipbuilding, aggregate and power plant construction. Due to the flow-favourable bulge, they may be used both horizontally and vertically.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

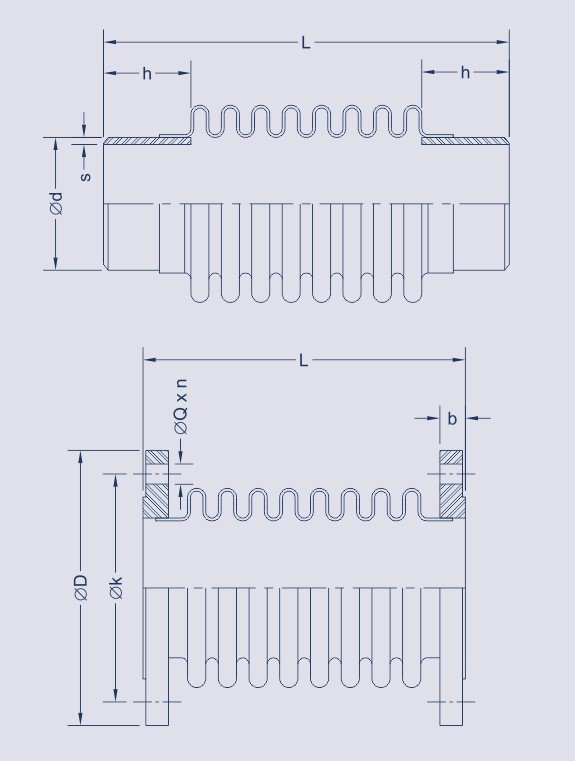

METAL Expansion Joints

Metal expansion joints

Used to compensate for pipe expansions, as vibration dampers, as installation expansion joint for non-flooding pipes or to facilitate installation of pipe fittings.

The core piece is the parallel corrugated, twist-free metal bellows, mainly made of stainless and acid-resistant steel alloys.

Materials

The standard versions of the steel bellows expansion joints consist of a stainless steel bellows made of materials 304ss – 316ss and 321ss with connecting parts made of carbon steel.

The expansion joints can also be manufactured from other stainless alloys and, for higher temperatures, from highly heat-resistant alloys 1.4828, Inconel, Hastelloy and the like.

Area of application

All expansion joints, which have neither an inner guide tube nor an outer protection tube, can absorb axial, angular and lateral movements as well as vibrations. Therefore, these types have a very versatile application and can be used for practically all cases.

Temperature

The permissible temperature of the standard versions with connecting parts made of carbon steel is up to +400 °C.

At higher temperatures, the connecting parts must also be made of alloyed steel.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.

REAFLEX AND REATEX

Elastomer- and fabric-expansion joints for flue gas and desulphurisation

KLINGER Kempchen has developed chemically and thermally durable fabric expansion joints for flue gas desulphurisation (FGD) waste incineration and chemical plants:

» ReaFlex for temperatures up to 205 °C

» ReaTex for temperatures above 260 °C

ReaFlex Elastomer Expansion Joints

are manufactured from elastomer bands reinforced with wire mesh, wire weave or fabric fibre glass. They are available in U-shape or band type for circular or angular ducts. For angular ducts, expansion joints can be manufactured with or without a bulge in the edge area. The design with a preformed bulge shows increased axial movement compensation.

ReaTax Fabric

are manufactured from PTFE coated glass fabric fibres. This combination of materials has shown superior performance at media temperatures of up to 260 °C. No pre-insulation is necessary at temperatures below this point. For higher temperatures, inner pre-insulation must be installed. Outer insulation is not permitted.

Downloads

Enclosed you will find downloads such as product documentation, product data sheet, safety information and gasket characteristics.